Effective stock inventory management is essential for running a successful Shopify store. Without the right strategy, you risk stockouts, overstocking, and lost revenue. By tracking sales trends, monitoring inventory levels, and using data-driven insights, you can optimize your stock and meet customer demand.

In this blog post, we’ll explore key strategies to improve inventory management and how Lebesgue’s Stock Inventory feature can help you stay ahead.

Why Is Stock Inventory Management Important for Shopify?

Effective stock inventory tracking and management are essential for the success of any Shopify eCommerce business.

They help prevent stockouts, which can lead to lost sales and frustrated customers, and avoid overstocking, which can tie up valuable resources and lead to increased storage costs. Maintaining an optimal balance between supply and demand minimizes waste, improves cash flow, and allows for better allocation of resources toward business growth.

By analyzing inventory data, you gain insights into sales trends that enable accurate demand forecasting and improved coordination with marketing strategies. This approach helps you stay prepared for seasonal fluctuations in demand and promotional efforts while avoiding the risks of advertising out-of-stock products.

Automated inventory systems also reduce errors, simplify reordering, and keep stock levels consistent across multiple sales platforms, improving both operational efficiency and customer experience.

Effective inventory management also reduces shrinkage from theft or damage, supports compliance with legal and safety standards, and reinforces the business’s ability to scale.

How To Improve Stock Inventory Management?

To improve stock inventory management, you need to track inventory in real time, forecast demand accurately, and optimize reorder points.

However, improving stock inventory management starts with focusing on the critical factors influencing your business’s operational efficiency and profitability.

To improve stock inventory management, focus on the following key areas:

- Identifying high-selling products that are at risk of running out.

- Analyzing overall product performance and availability.

- Monitoring the demand and stock levels of specific product variants.

- Assessing the overall health and balance of your inventory.

You can take proactive steps to prevent stockouts, reduce overstocking, and align your inventory with customer demand. In the next sections, we’ll break down each of these areas and explore strategies to streamline your stock management process.

Identifying high-selling products that are at risk of running out

Identifying high-selling products at risk of running out involves using systems that prioritize products based on critical metrics such as orders, revenue, or daily demand.

Sorting by these metrics helps pinpoint which items are driving the most sales and require immediate attention.

Identifying high-selling products at risk of running out is crucial for maintaining stock levels and preventing lost sales. Here’s how you can do it effectively:

- Analyze sales data,

- Calculate stock turnover rate,

- Monitor inventory levels against sales velocity,

- Use automated alerts and forecasting tools,

- Consider lead times and supply chain factors,

- Set reorder points, and

- Monitor seasonal trends.

To prevent stockouts, it’s essential to track high-selling products and monitor inventory levels closely. Analyzing sales velocity helps you understand how quickly items are selling compared to available stock.

Using automated alerts and forecasting tools can help predict when to reorder before running out. It’s also important to factor in supplier lead times to avoid delays in restocking.

By adjusting reorder points based on demand patterns and seasonal trends, you can keep your inventory balanced and ensure products remain available.

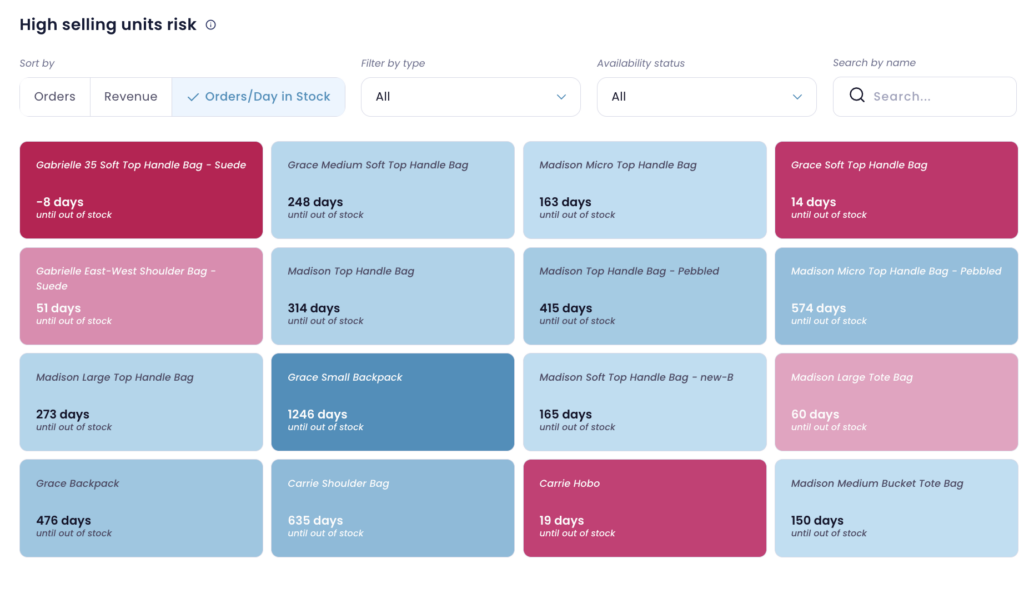

Lebesgue: AI CMO uses a method of color-coded alerts to provide a visual way to highlight stock levels—red shades indicate critically low stock, pink shades signify items that need attention soon, and blue shades represent stable inventory.

Also, Lebesgue gives you the option to filter units by product type or availability status allowing you to refine their focus, ensuring that only the most relevant products are prioritized.

Additionally, metrics like “days until out of stock” provide clear timelines for restocking, making it easier to anticipate inventory needs.

Analyzing overall product performance and availability

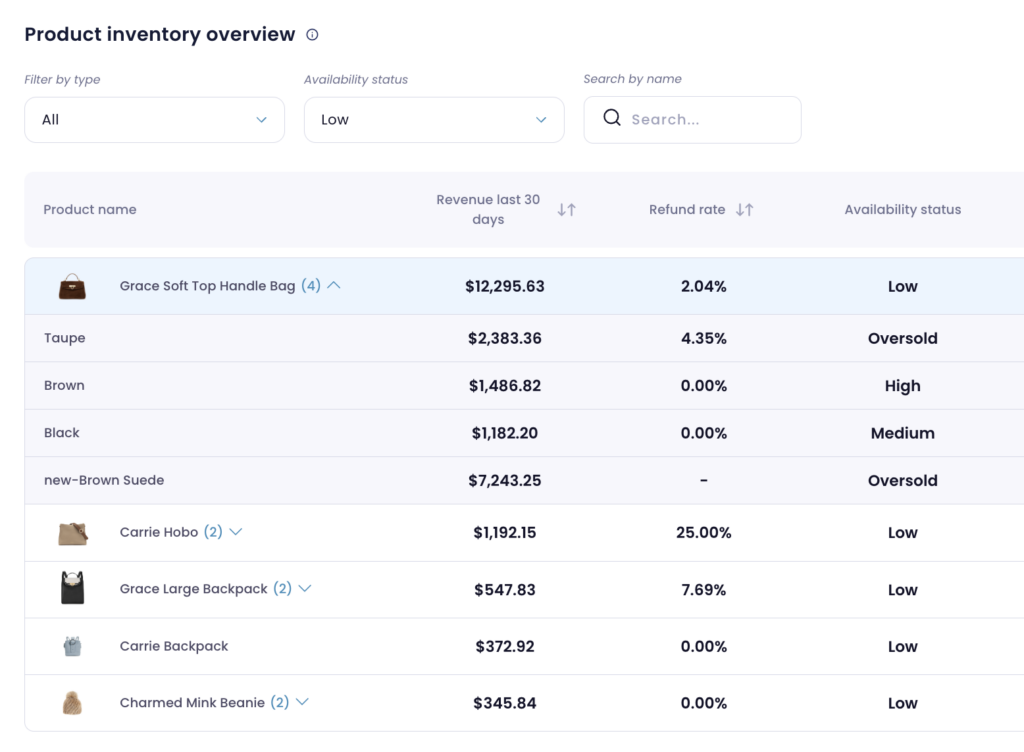

Consistently monitoring your product inventory overview is essential for maintaining an efficient and profitable operation.

By keeping track of inventory levels, estimated days until stock runs out, and product availability statuses, you can make smarter decisions about inventory management.

Continuous tracking helps improve demand forecasting by providing insights into product performance metrics like orders and sales trends, making it possible to align restocking with customer demand.

With this data, you can prioritize high-demand products, allocate resources efficiently, and phase out underperforming items, ensuring a streamlined and cost-effective inventory management process.

Understanding sales trends—such as daily sales over the past week and month—along with retention rates gives you actionable insights to optimize your inventory and marketing strategies.

Short-term sales trends reveal immediate shifts in demand, allowing you to quickly adapt by increasing stock or running promotions for trending products. Meanwhile, long-term sales data uncovers broader patterns, helping you identify seasonal trends and maintain consistent bestsellers.

Retention rates show how loyal your customers are and which products keep them coming back, helping you decide what to promote or improve.

By combining these metrics, you can create targeted campaigns, optimize stock levels, and ensure your inventory strategy aligns with customer demand—driving growth and profitability.

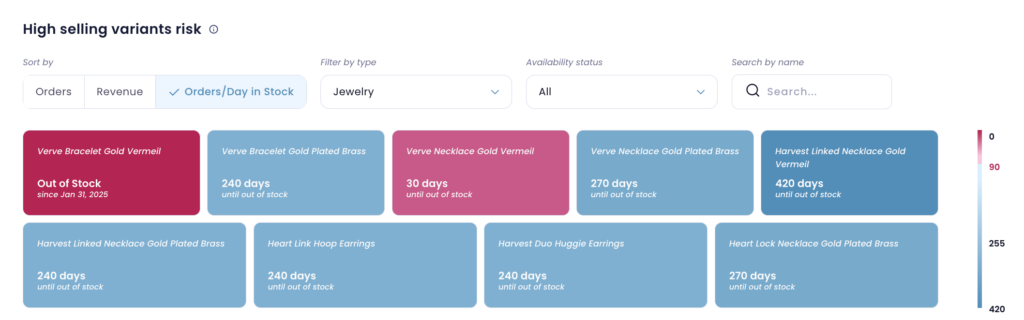

Monitoring the demand and stock levels of specific product variants

Unlike simply monitoring high-selling products, identifying successful variants, such as specific colors, sizes, or materials, enables businesses to cater to diverse customer preferences.

These variants often play a pivotal role in purchase decisions, and failing to stock them can result in abandoned sales and dissatisfied customers. Meeting specific preferences builds trust and encourages repeat purchases, making variant availability a key factor in customer retention.

Moreover, popular variants frequently outperform the general product line in revenue generation, making them essential for maximizing profitability.

Lebesgue: AI CMO provides clear alerts for at-risk variants, such as those running low on stock, empowers businesses to allocate resources effectively, and maintains high-demand options available.

By consistently offering a broad selection of well-stocked variants, businesses can satisfy customer needs, foster loyalty, and maintain a competitive edge in the market.

Tracking availability status of your inventory

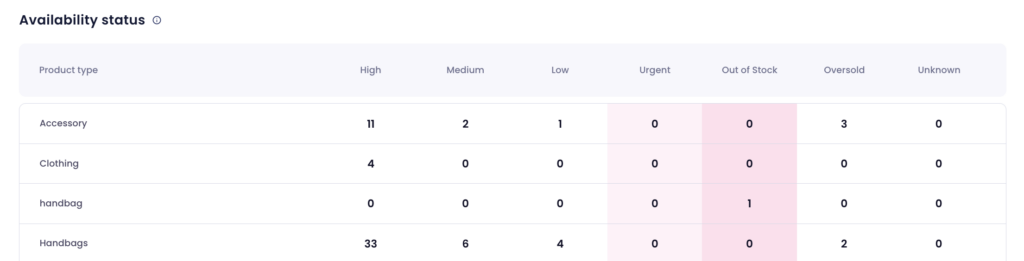

Tracking the Availability Status of product categories offers a clearer and more actionable overview of your inventory compared to simply monitoring inventory levels.

While inventory levels tell you the number of units available for a specific product, Availability Status provides a categorized view of your stock across various levels, such as high, medium, low, urgent, out of stock (OOS), and oversold. This categorization helps you quickly identify which products or categories need immediate attention, allowing for faster and more targeted decision-making.

For example, rather than manually analyzing inventory levels for hundreds of products, availability status gives an at-a-glance summary of critical issues. If a product category, like handbags, has several items marked as “urgent” or “out of stock,” it becomes immediately clear where resources should be directed.

This system prioritizes action by highlighting problem areas, such as products at risk of stockouts, overstocked items, or unknown statuses needing clarification. In contrast, relying solely on raw inventory numbers might delay decisions, as further analysis is required to understand their implications.

Best way to track availability status

The most efficient way to keep track of availability status is through automated inventory management tools that categorize products based on predefined thresholds. These tools provide a real-time snapshot of inventory health across categories, enabling teams to make proactive decisions without the need for extensive manual calculations.

Dashboards, like the one in Lebesgue’s Availability Status feature, offer visual and intuitive summaries, showing the distribution of products across availability levels. This not only streamlines the decision-making process but also assures that resources are allocated effectively to maintain a balanced inventory and meet customer demand efficiently.

Summing Up

Effective stock inventory tracking and management are fundamental to the success of any Shopify eCommerce business.

By focusing on critical aspects like high-selling products, key product variants, and availability status, businesses can prevent stockouts, reduce overstocking, and align their inventory with customer demand.

Tracking sales trends, retention rates, and inventory performance empowers businesses to optimize their strategies, allowing them to consistently meet customer needs and achieve profitability.

With tools like Lebesgue’s Stock Inventory feature, you can automate these processes and gain actionable insights into their inventory health. The feature simplifies decision-making by highlighting at-risk items, tracking product performance, and categorizing availability status, allowing for faster, data-driven responses to shifting market demands.